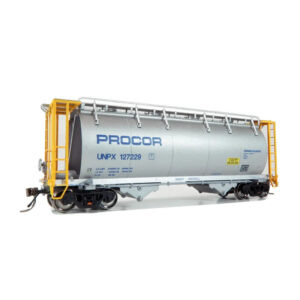

Procor 3000cf Aluminum Covered Hopper

Prototype Information

In the early 1980s, sodium chlorate began replacing chlorine as a bleaching agent in paper production. Railroads had historically transported it in solution form by tank car, but rising demand called for a more efficient method. Moving it as crystals in covered hopper cars offered a solution—but the material’s corrosive nature posed a challenge.

Procor developed an all-aluminum covered hopper to handle the chemical. Compared to conventional cars, it had lower cubic volume (3,000 cu. ft.) and higher capacity (100 tons). Each gate featured a sparger system to introduce hot water, liquefying the crystals for discharge.

Procor built the first 20 cars at Oakville, Ontario in 1982, adding steel end structures and retractable handrails. Production ran until 2001. Over time, Procor, along with NSC and Thrall, produced more than 1,300 aluminum sodium chlorate hoppers.

Showing all 2 results

-

Rapido HO Procor 3000cf Aluminum Covered Hopper Procor

$50.00 Select options This product has multiple variants. The options may be chosen on the product page -

Rapido HO Procor 3000cf Aluminum Covered Hopper Procor w/ Handrail “Wordmark”

$50.00 Select options This product has multiple variants. The options may be chosen on the product page