Description

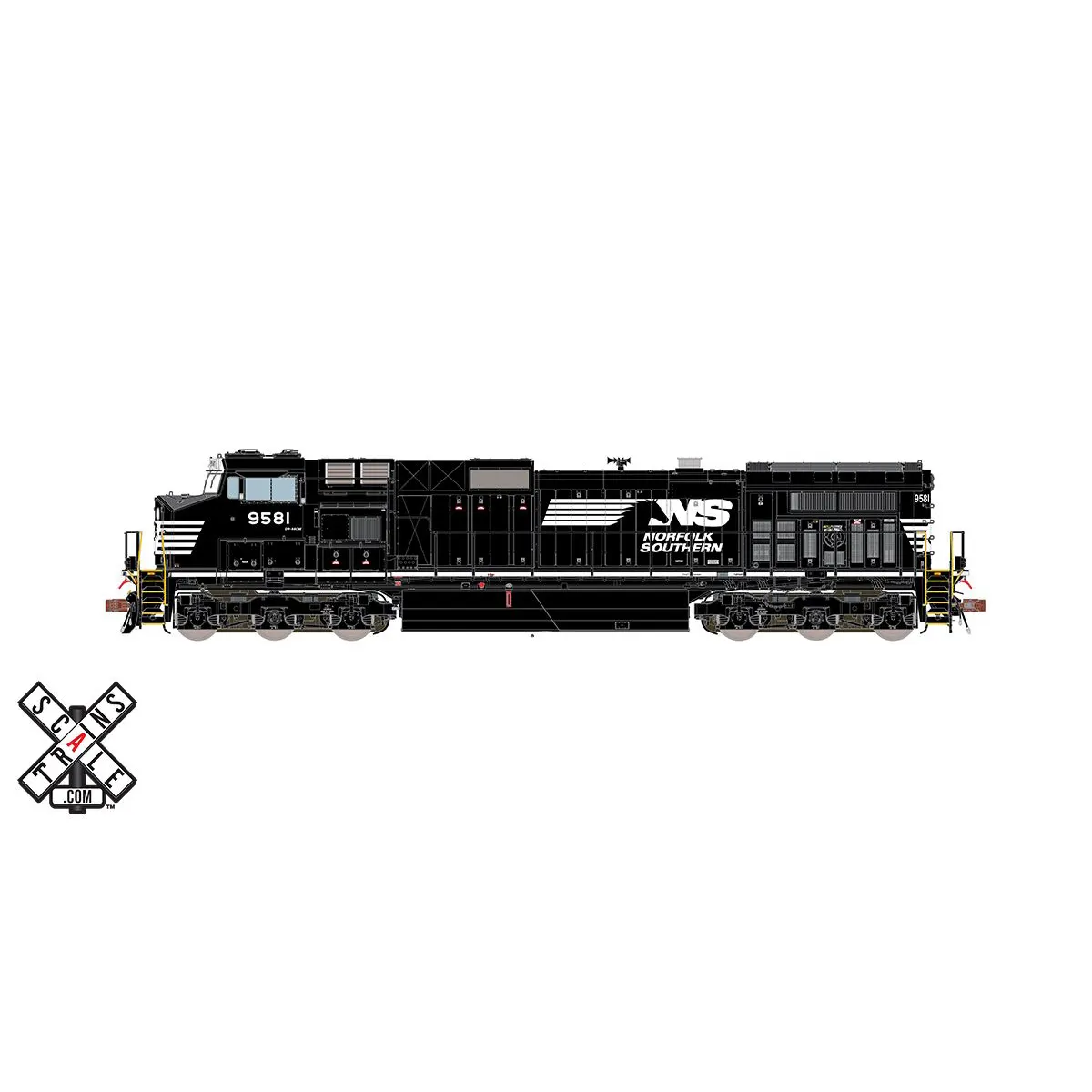

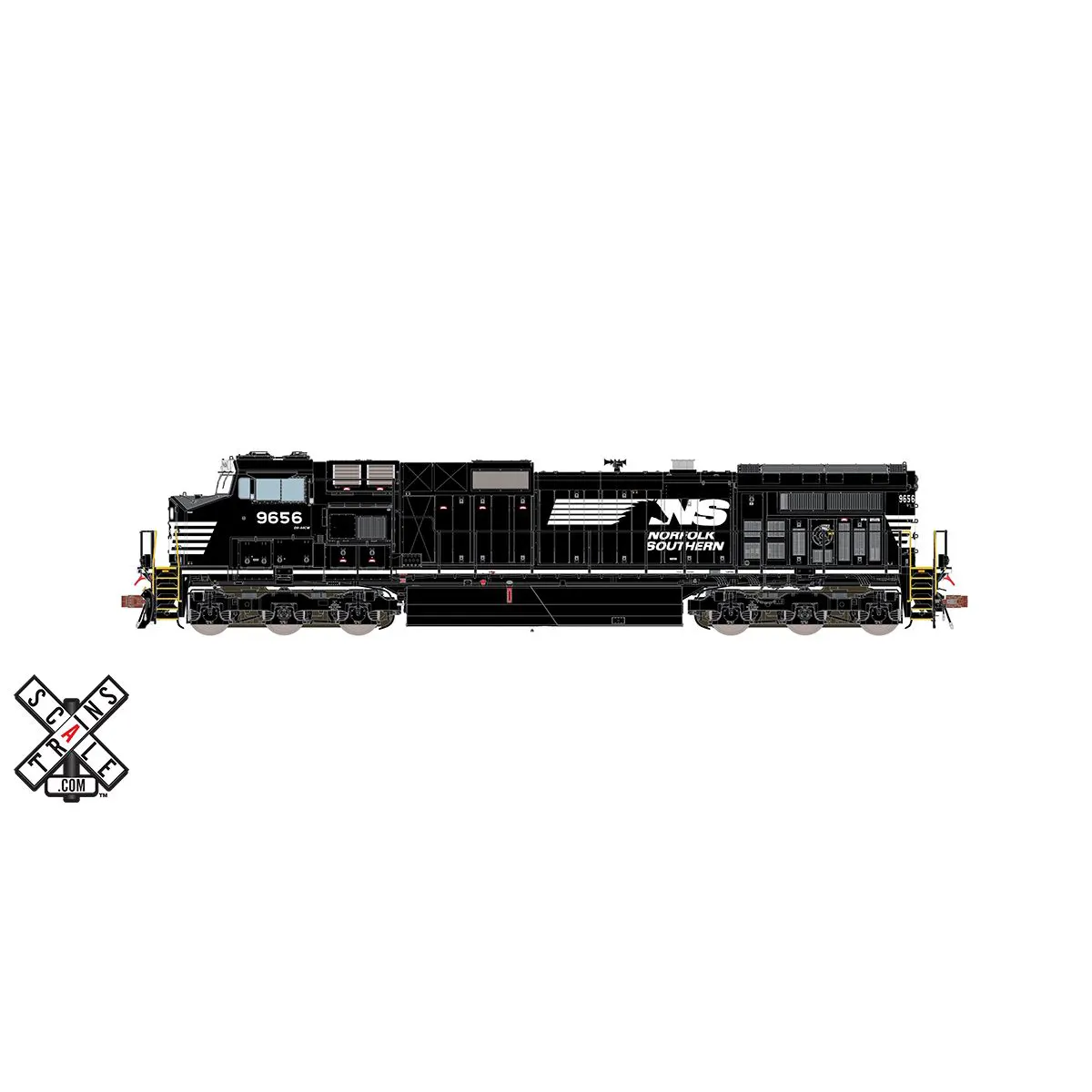

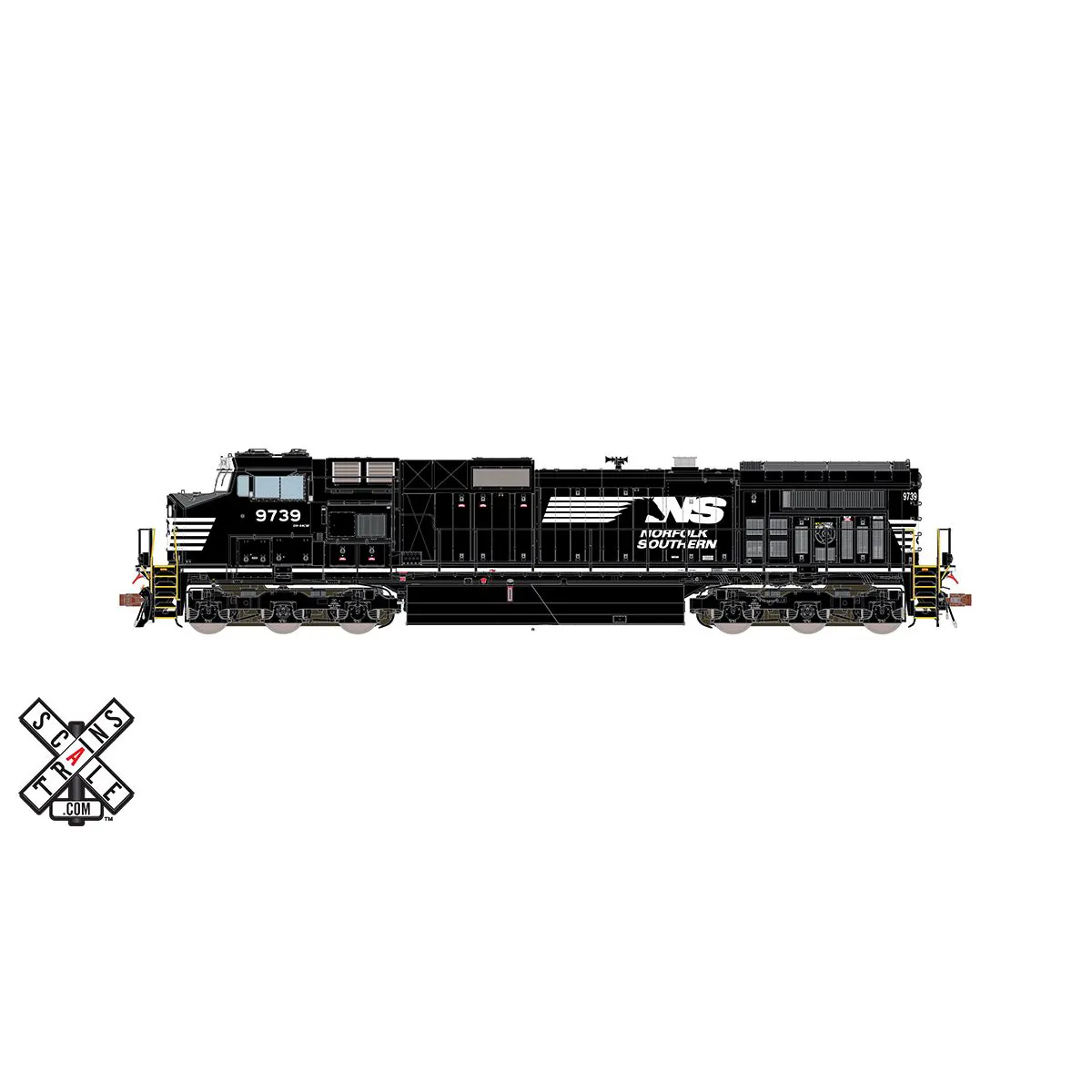

Railroad Short Name: NS

General Electric wrestled the title of top domestic locomotive builder from EMD during the late 1980s with their Dash-8 series. GE once again positioned themselves to shakeup the locomotive world yet again less than a decade later. Entering the 1990s, GE completely revamped their locomotive lineup by utilizing customer feedback, learning from experience gained from previous locomotive series, and improvements in technology.

A single C44-9W demonstrator unit, numbered 8601, made its debut in 1993 (and later became C&NW 8601). While similar at first glance to predecessor models like the C40-8 and C40-8W, the Dash-9 series featured a few notable physical differences. Built on a slightly longer platform that allowed for a massive 5,000 gallon fuel tank, Dash-9s also featured thicker radiator “wings” at the rear of the carbody. This is usually the quickest way to differentiate them from previous models.

Thanks to its long production span and customer options, small detail differences could be noted between various customer orders. This includes changes with HVAC system vendors (the large “A/C” box behind the cab on the conductors side), engine cab profile, radiator lifting lugs, hood end, trucks, fuel tank, stepwells, operator’s cab, and even handrail profiles.

The C44-9W proved to be extremely popular over its production span with over 3,500 locomotives being sold new to ATSF, BC Rail, BNSF, CN, C&NW, NS (including 100 spartan cab equipped versions, nicknamed “Top Hats”), QNS&L, SP, and UP.

Locomotive Features:

- Era: 2015 to present

- NS 9535-9744, built December 2000 through December 2001

- Fully-assembled

- Multiple road numbers

- No ground lights (prototype not equipped)

- Operating LED front, rear, and side walkway lights*

- Operating LED front and rear deck-mounted alternating ditch lights**

- LED-illuminated high-mount number boards*

- Front high (cab) mounted headlight

- LSL (Locomotive Speed Limiter) indicator lights on cab sides (non-operating)

- Tall snowplow with open doors and grab irons

- Semi-scale coupler buffer equipped with durable metal semi-scale Type E knuckle couplers

- 5-step stepwells with see-through steps

- Walkway with front and rear anticlimber

- GE “nub” pattern walkway tread

- Wide profile end handrails

- Nose door with window

- Two-piece nose top grab irons

- Electrical cabinet access doors with barrel bolt safety latches

- Battery cabinet access door with latch

- GE safety cab with three (3) side windows

- Cab interior with detailed back wall and front dash, high-back seats, conductor’s work station, and engineer’s AAR-style control stand

- Tinted cab side windows

- Medium mirror mounted in front of sliding cab side windows on both sides; additional small mirror on right side

- Retrofitted with JEM Communications PTCantenna farm with Sinclair antennas

- Electrical cabinet with barrel bolt safety latches, step on rear, and spare knuckle basket

- Dayton-Phoenix GE Side-Mount Model 2806220 HVAC unit

- Dynamic brake intake panels

- Continuous reinforcement rib under dynamic brake intake grilles

- Late dynamic brake exhaust

- Late angled engine cab profile with raised “dot” treadplate on centerline

- Lost-wax brass cast Nathan AirChime K5LAR24 horn mounted on engine cab

- Late non-flanged exhaust stack housing

- “Bathtub” exhaust silencer

- 26 individually-applied etched metal see-through radiator intake and exhaust grilles on sides and top of radiator compartment

- Late radiator door grilles (alternating heights)

- Standard brake wheel

- Low-mounted rear sand fill

- Late lifting lugs on ends of radiator wings

- Accurately profiled frame with separately-applied plumbing and traction motor cabling

- Late Hi-Ad trucks with cantilever struts on all four sideframes, and flange lubricator sticks

- Rotating axle bearing caps

- No speed recorder

- Dual Graham-White (Prime) 975-075 Air Filters

- Graham-White 994-500 Series Air Dryer

- 5,000-gallon fuel tank with angled weld seam and clean out on left side

- Single fuel filler per side

- Round and vertical analog fuel gauges, and digital fuel gauges

- Fuel tank mounted electronic bell

- Separate air tanks with lower mounting brackets, connector pipe, and connector pipe cover

- Late, triangular handbrake chain bracket

- Spare coupler knuckle holders on rear pilot face

- Factory-applied detail parts: wire grab irons, spare knuckles, trainline hoses with silver gladhands, 3-hose MU clusters with silver gladhands, uncoupling levers, windshield wipers, mirrors, sunshades, and more

- Motor with 5-pole, skew-wound armature

- Dual flywheels

- All-wheel drive

- All-wheel electrical pick-up

- Directional LED headlights

- Printing and lettering legible under magnification

- Operates on Code 70, 83, and 100 rail

- Packaging safely stores model

- Minimum Radius: 18”

- Recommended Radius: 22”

DCC & sound ready locomotives also feature:

- Operate on DC layouts

- DCC ready with 21-pin connector

Reviews

There are no reviews yet.